The textile and fashion industry has a long and complex supply chain. Each production step has an environmental impact due to water, material, chemical, and energy use.

Many chemicals used in textile manufacturing are harmful to the environment, factory workers, and consumers. It’s an environmental nightmare we can’t ignore.

The fashion industry produces 150 billion garments a year. 87% (40 million tons) end up in a landfill where they smolder in an incinerator and pollute the air. But fast fashion has a significant impact on the environment beyond landfill accumulation.

Fashion manufacturers have drastically increased the material throughput in the system.

Fashion brands are now producing almost twice the amount of clothing today compared to just 20 years ago, a 2020 study published by Nature Reviews Earth & Environment points out.

“The fashion industry is facing increasing global scrutiny of its environmentally polluting supply chain operations,” researchers wrote. “Despite the widely publicized environmental impacts, however, the industry continues to grow, in part due to the rise of fast fashion, which relies on cheap manufacturing, frequent consumption, and short-lived garment use.”

The production of clothes generates a significant amount of greenhouse gas emissions, including carbon dioxide and methane, which contribute to climate change. The fashion industry is responsible for about 4% of global carbon emissions, according to the United Nations Environment Programme’s Sustainable Fashion: Communication Strategy 2021 – 2024. The fashion industry produces as much emissions as Germany, France, and the U.K. combined. Unchecked fashion production will account for 26% of all carbon emissions by 2050.

Additionally, the highly toxic dyeing and finishing process of clothes involves a vast amount of water.

It ultimately ends up contaminating rivers and other water bodies with harmful chemicals, disrupting natural ecosystems.

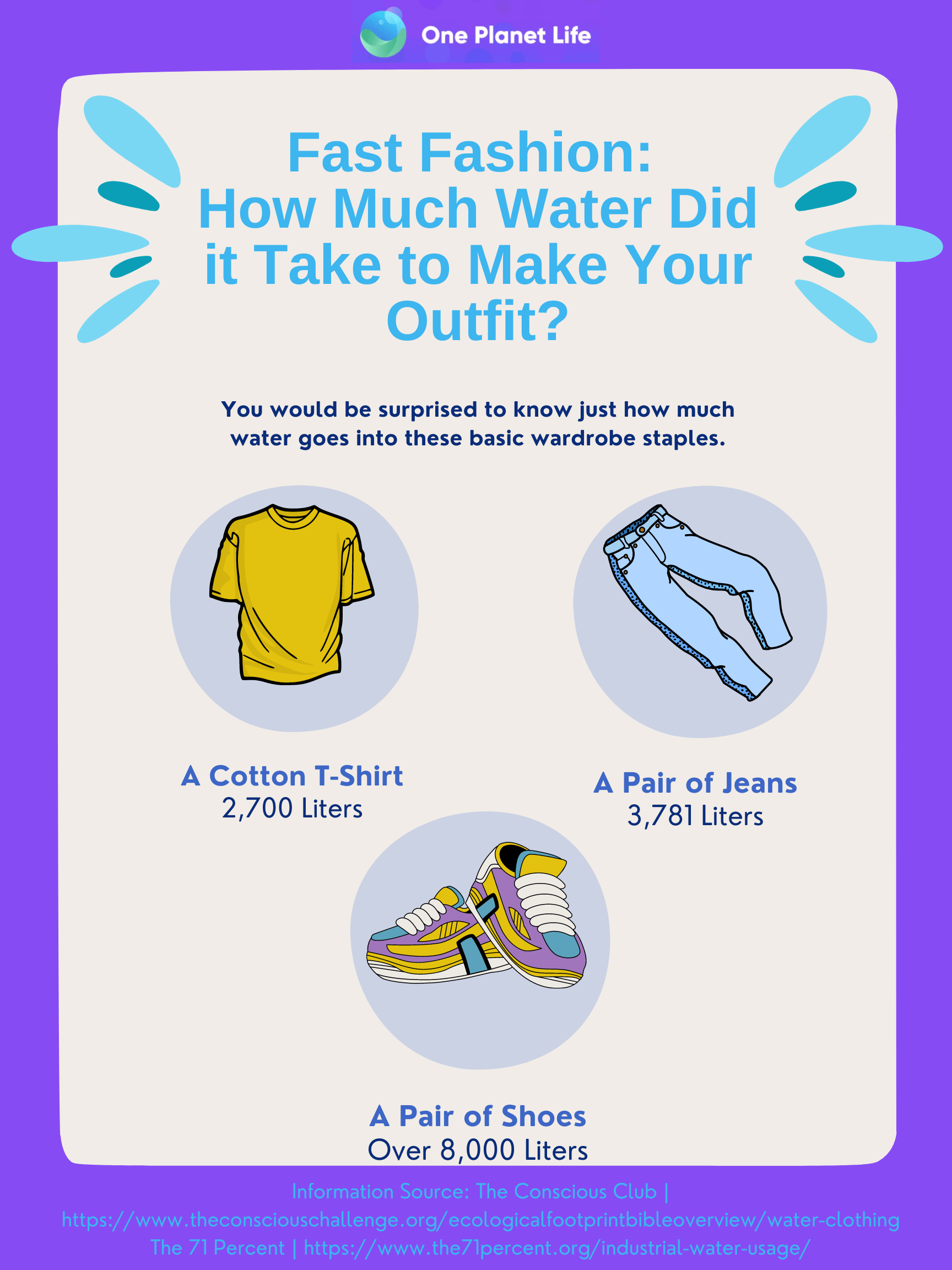

To produce a single cotton t-shirt, it takes over 2,700 liters of water, or 900 days’ worth of drinking water, according to The Conscious Club. A pair of jeans takes 3,781 liters of water from cotton production to delivery of the final product to stores. That equates to the emission of around 33.4 kilograms of carbon equivalent. A pair of shoes? Estimates quote over 8,000 liters of water are consumed in the production of a standard pair.

Microfibers from quickly deteriorating fabrics have become a topic of concern among environmentalists.

Up to 85% of human-made pollution on shorelines is from microfibers, according to a 2019 study from the Sheffield Business School. An additional half million tonnes of microfibers are discarded into the oceans annually.

In fact, 62% of all clothing is made partially or entirely of synthetic fibers such as polyester, which is a crude oil derivative. Petroleum, a non-renewable resource, inflicts significant negative impacts on the earth.

Garments made with blends of synthetic fibers are more difficult to recycle. Statistics reflect this stark reality, as only 1% of all discarded clothing is actually recycled. For true recycling to take place, clothing must be collected, sorted, and distributed to recyclers. These systems are grossly inefficient and time and labor-intensive.

However, people are striving to find alternative methods to address this problem.

In Sweden, researchers are taking innovative steps towards fiber recycling, a process called Blend Re:wind, to try to alleviate the amount of clothing that ends up in landfills.

“The Blend Re:wind separation process makes it possible to recycle mixed-textile clothing, for example, cotton-polyester blends,” according to the Rise Institutes of Sweden. “The reclaimed fibers can then be used as new raw materials in existing textile manufacturing processes.”

Alternative base materials are another hopeful prospect for designers and consumers to consider.

A Finnish firm, Infinited Fiber, has developed a cotton alternative called Infinna which is the product of recycled material through a complex process.

“It’s a premium quality textile fiber, which looks and feels natural – like cotton,” CEO Petri Alava told the BBC last September. “And it is solving a major waste problem.”

With enough global business investment to scale such systems to meet the demand, these technologies could drive 80% circularity in the fashion industry.

Fortunately, there is a lot of power in consumer decision-making that can help to reverse the fast fashion trend.

The average American throws away about 80 pounds of clothing every year. Consumers can choose to buy less and consider the concept of a capsule wardrobe, where they purchase a few high-quality essential items rather than numerous cheap ones that will deteriorate quickly.

Secondhand options are an excellent alternative.

Many retailers now offering used clothing sections where one can find gently used clothes at an affordable price. Patagonia, for example, has set up Worn Wear, a program where customers can get existing garments repaired or buy and trade in gently used items from the brand.

While they may cost more upfront, sustainable brands are also worth considering.

They promote ethical production methods and prioritize organic materials, fair labor, and safe working conditions. With these changes in mind, paying more for a staple item in your closet from a sustainable brand may be worth the cost upfront, as these garments can last longer than those from famous “fast fashion” brands like Shein, Zara, and H&M.

Consumers can also extend the lifespan of their clothes by repairing them instead of immediately throwing them out. Donating clothes that no longer serve a purpose instead of throwing them into landfills is also a sustainable option, and some brands and stores now have recycling programs that can take back unwanted clothes and recycle them properly.

The environmental impact of fast fashion is significant and requires urgent action to achieve sustainable and circular production practices.

To make fundamental changes in the fashion industry, there needs to be a deceleration of manufacturing and the introduction of sustainable practices throughout the supply chain. It also requires a shift in consumer behavior to decrease clothing purchases and increase garment lifetimes.

Small changes in consumer behavior, such as buying less, shopping secondhand options, and purchasing from sustainable brands, can make a big difference in reducing the negative impacts of fast fashion.

Break the cycle of fast fashion. Find out how.

Dive deeper into the world of fashion with these recommended reads:

Written by Carley Kimball

Freelance Journalist and OPL Content Contributor